Artist Profile

Barry Biesanz

He found Woodturner’s Heaven

By Sandy Gregor

Imagine all the cocobolo- arguable on of the world’s most beautiful woods – that you could want at your fingertips. That alone might make some folks think that they were in woodturner’s heaven!

Imagine, too working in an open-air shop where the weather is perpetually “sun-kissed” spring, where there is an apprentice to sweep up your shavings, and someone else who does all the finish sanding, taking all your turnings to an exquisite level of perfection.

But let’s not stop there. Imagine that in this adopted land of yours, you are regarded as the country’s preeminent craftsman, called on by the foreign ministry to provide gifts to visiting royalty and presidents. La Pura Vida – or the pure life as the Costa Ricans say – is not a fantasy at all. It’s the life of Barry Biesanz!

THE MAN

It was anything but an ordinary beginning that led to this charmed life. Born in New Orleans, Barry grew up mostly in Detroit. When he was six, his family spent a half year in Guatemala where he began to blend his American heritage with Latin customs, eating homemade tortillas smeared with peanut butter.

His father, a sociologist, and his mother, a successful textbook writer, took Biesanz and his two siblings all over the globe. The family was highly intellectual and at a loss, in Barry’s version of family history, when confronted with anything so practical as a flat tire. Hence his interest in woodworking developed as a kind of corrective balance to the family forces.

Biesanz is an American by birth and sensibility, but he is a Costa Rican in all else. Now a naturalized citizen, he runs a successful crafts and fine arts woodworking business. He also manages a 60-hectare family farm that he is reforesting in native hardwoods and is developing an ecological preserve.

THE BUSINESS

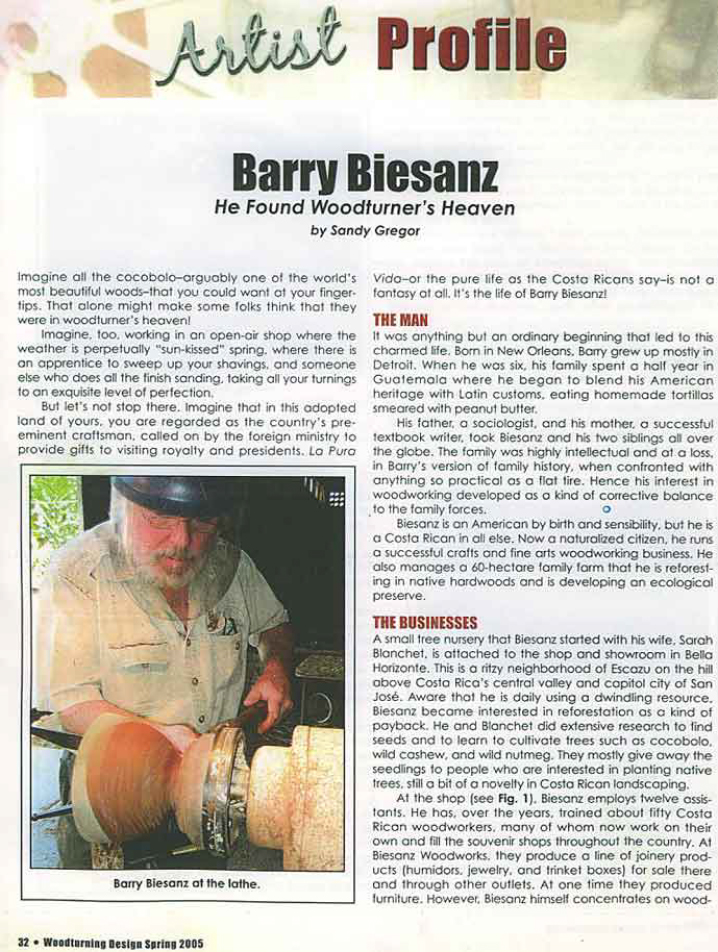

A small tree nursery that Biesanz started with his wife, Sarah Blanchet, is attached to the shop and showroom in Bello Horizonte. This is a ritzy neighborhood of Escazu on the hill above Costa Rica’s central valley and capitol city of San José. Aware that he is daily using a dwindling resource, Biesanz became interested in reforestation as a kind o payback. He and Blanchet did extensive research to find seeds and to learn to cultivate trees such as cocobolo, wild cashew and wild nutmeg. They mostly give away the seedlings to people who are interested in planting native trees, still a bit of a novelty in Costa Rican landscaping.

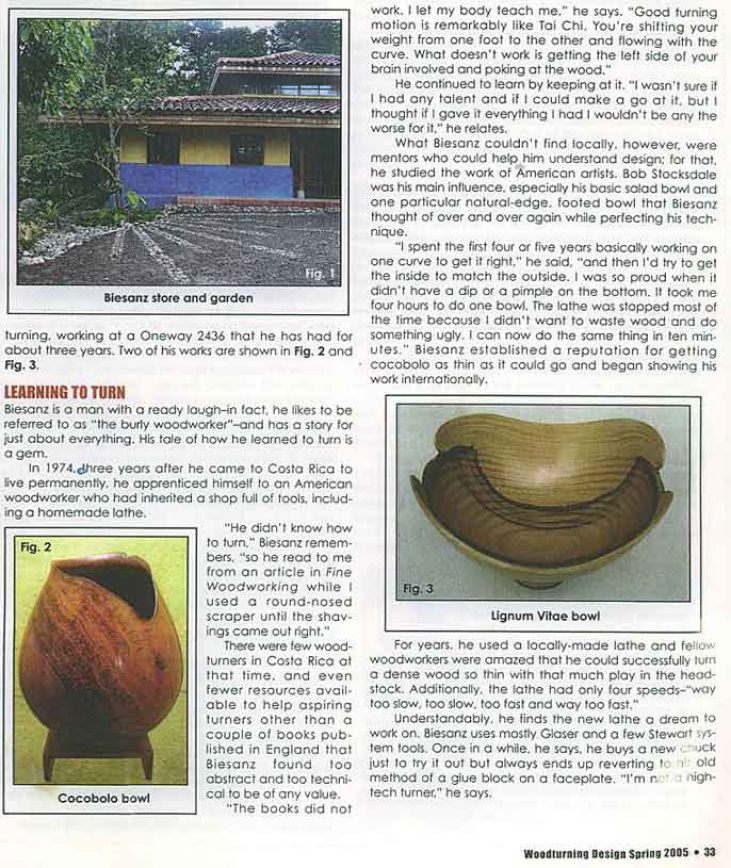

At the shop (See Fig. 1) Biesanz employs twelve assistants. He has, over the years, trained about fifty Costa Rican woodworkers, many of whom now work on their own and fill the souvenir shops throughout the country. At Biesanz Woodworks, they produce a line of joinery products (humidors, jewelry and trinket boxes) for sale there and through other outlets. At one time they produced furniture. However, Biesanz himself concentrates on woodturning, working at a Oneway 2436 that he has had for about three years. Two of his works are shown in Fig. 2 and Fig. 3.

LEARNING TO TURN

Biesanz is a man with a ready laugh-in fact, he likes to be referred to as “the burley woodworker” and has a story for just about everything. His tale of how he learned to turn is a gem.

In 1974, three years after he came to Costa Rica to live permanently, he apprenticed himself to an American woodworker who had inherited a shop full of tools, including a homemade lathe.

“He didn’t know how to turn,” Biesanz remembers, “so he read to me from an article in Fine Woodworking while I used a round-nosed scraper until the shavings came out right.”

There were few woodturners in Costa Rica at that time, and even fewer resources available to help aspiring turners other than a couple of books published in England that Biesanz found too abstract and too technical to be of any value.

“The books did not work. I let my body teach me” he says. “Good turning motion is remarkably like Tai Chi. You’re shifting your weight from one foot to the other and flowing with the curve. What doesn’t work is getting the left side of your brain involved and poking at the wood.”

He continued to learn by keeping at it. “I wasn’t sure if I had any talent and if I could make a go at it, but I thought if I gave it everything I had I wouldn’t be any the worse for it,” he relates.

What Biesanz counldn’t find locally, however, were mentors who could help him understand design; for that, he studied the work of American artists. Bob Stocksdale was his main influence, especially his basic salad bowl and one particular natural-edge footed bowl that Biesanz though of over and over again while perfecting his technique.

“I spent the first four or five years basically working on one curve to get it right,” he said, “and then I’d try to get the inside to match the outside. I was so proud when it didn’t have a dip or a pimple on the bottom. It took me four hours to do one bowl. The lathe was stopped most of the time because I didn’t want to waste wood and do something ugly. I can now do the same thing in ten minutes.” Biesanz established a reputation for getting cocobolo as thin as it could go and began showing his work internationally.

For years, he used a locally-made lathe and fellow woodworkers were amazed that he could successfully turn a dense wood so thin with that much play in the headstock. Additionally, the lathe had only four speeds – “way too slow, too slow, too fast and way too fast.”

Understandably, he find the new lathe a dream to work on. Biesanz uses mostly Glaser and a few Stewart system tools. Once in a while, he says, he buys a new chuck just to try it out but always end up reverting to his old method of a glue block on a faceplate. I’m not a high tech turner.” he says.

METHODS

The cocobolo he buys usually comes in short lengths, cut so the harvester can carry the pieces out. “It’s not near the road. If it were, it would have been harvested long ago.” he added. Log ends are painted, and the wood is stored out of the sun.

He is careful about what he buys because the wood is often poorly stored and cracked. Despite the rarity of cocobolo, Biesanz admits, “there is an awful lot of inefficiency in Latin American forestry practices.”

Biesanz’ finished work retails from $90 tp $300 with some pieces going for as much as $12,000. But, despite the high end of his sales range, he rarely works in large sizes because it is difficult to acquire the right log. Cocobolo trees often have a void in the center several inches in diameter. “A friend of mine cut one of the biggest cocobolo trees I’ve ever heard of, but it was entirely hollow – there were only a few inches of good wood. Was he ever disappointed.” he remarked.

Biesanz keeps about eight or ten bowls chucked up on faceplates waiting at his workbench. He glues the cocobolo blanks (and sometimes lignum vitae, one of the world heaviest woods) to the waste block with either cyanoacrylate glue or ordinary white glue. “People don’t believe me.” when he tells them to latter, he says, “but it works.”

He twice-turns most bowls, turning the first time with the wood “as wet as I dan get it.” The roughed out bowls are handed over to an assistant to be dated and completely coated with wax. They are then set aside in a large, airy storeroom – filled with other dry and drying blanks (see Fig. 4) where they wait at least a year before being returned to the lathe and turned to their final form. Assistants – working off the lathe- do all the final sanding to 400 or 500 grit, using a bevel-edged power sander, sometimes taking up to three hours per piece. Having help “more than doubles my production,” Biesanz says.

“When I first started, I’d say to myself, “I’m just roughing it; I can always change it later. It removes the censor,” says Biesanz. “But I rarely change it. At the finish stage, I’m basically just truing things up. I only change the form if I’ve been in a bad mood or was distracted when I roughed out.”

When Biesanz steps up to the lathe, he switches on a light, turns on a large fam, and puts on a helmet for safety. Since the shop is completely open to the outdoors on one side, the fan is all he needs to protect himself from the noxious cocobolo dust. “If I don’t my nose will run and my eye will water,” he says. But with some precautions, he doesn’t believe cocobolo presents serious allergy problems for most people. Out of fifty people who have worked in his shop, only a couple have had any serious reaction.

THE CREATIVE PROCESS

Biesanz is a broad reader and has thought deeply about the creative process. He spices his conversations about woodturning with quotes from everyone from Sufi masters (alongside hte wood products, he keeps a shelf of books on Sufi mysticism for sale) to Lewis Hyde, Tom Wolfe, and former president Jimmy Carter, himself a fellow woodworker. About the process of learning to turn, he likes to quote Woody Allen who said, “Ninety percent of success is just showing up.” To that Biesanz adds, “and the rest is sticking around.”

“If you don’t screw up,” he advises the beginner, “you are not trying. When you can be at peace with that and recognize it as part of the learning curve you’re getting somewhere. I’ve known people who were too pleased with their work.” he said. “you have to pat yourself on the back to keep going, and you have to be critical enough to improve. You have to have balance.”

If you are thinking of dropping by the shop in Escazu, it’s best to first visit www.biesanz.com for a map. Costa Rican businesses are far more subtly advertised than their American counterparts. You can see more of Barry Biesanz’ work in this country at the Northeast Gallery of Woodworking in Seattle, the One of A Kind in San Francisco, and the Idea Factory in New Orleans.